Wet Wells Are Out. OverWatch Is In.

The Wet Well Is Dead. OverWatch Is the Future.

For decades, wet wells have been the foundation of wastewater management. But their time has come to an end. The OverWatch pump system, developed by Industrial Flow Solutions and expertly installed by Rhino Pumps, is changing everything. If you are looking for a replacement for outdated wet well systems or searching for innovative wastewater solutions, this post is for you. Let us dive into why wet wells are becoming obsolete and how OverWatch is leading the transition.

The Problem with Wet Wells

Wet wells are underground tanks that collect wastewater. Since their introduction, they have caused constant problems. One of the most serious is ragging, a condition where wipes and solid debris clog the pumps. This results in frequent maintenance, increased safety risks, and costly repairs.

Traditional wet well setups also require workers to enter confined spaces, where they may be exposed to toxic gases such as hydrogen sulfide. These environments are dangerous and outdated. With more than two thousand installations around the world, the OverWatch system has proven that wet wells are no longer necessary. It provides a cleaner, safer, and more efficient solution.

How OverWatch Replaces the Wet Well

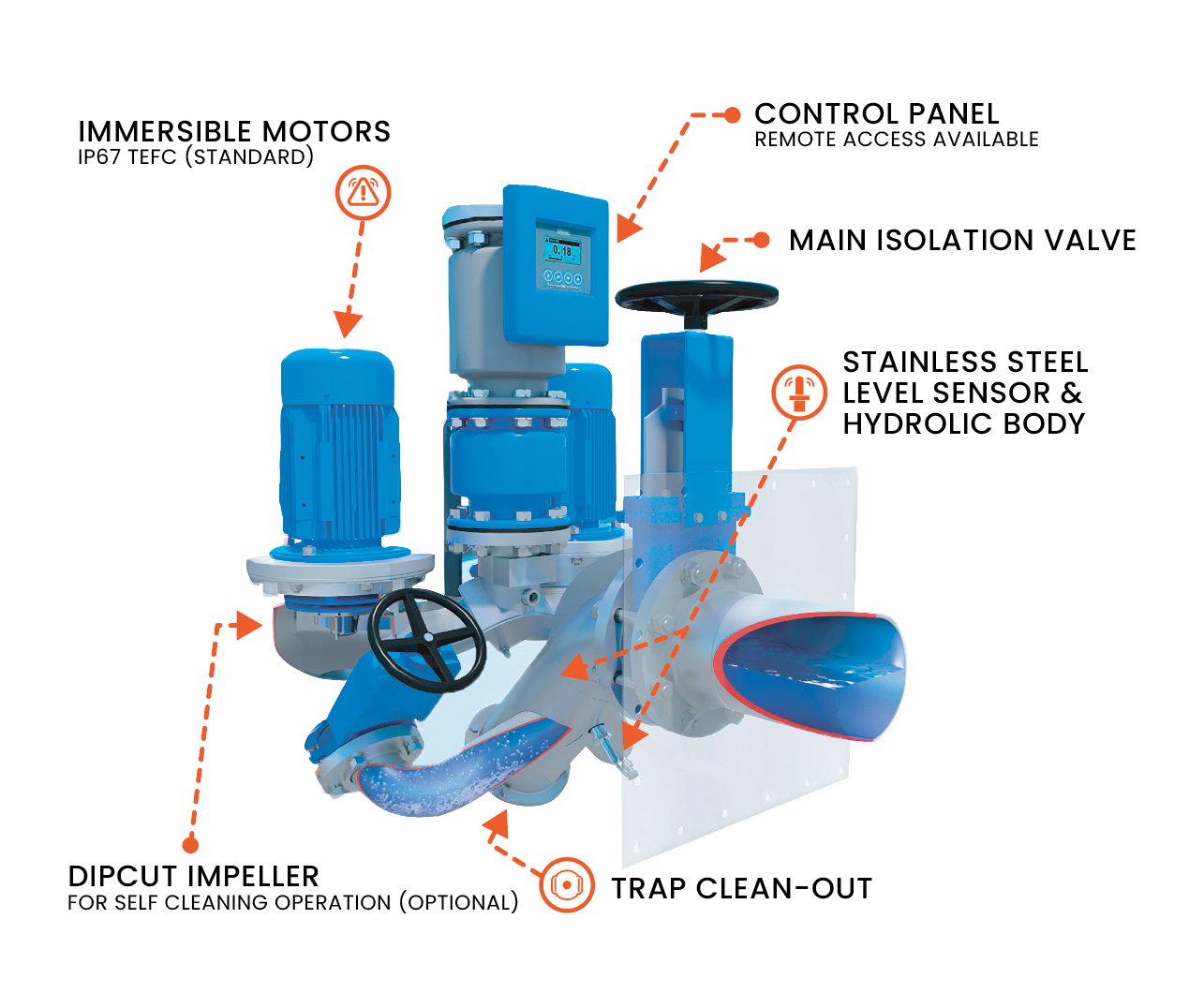

OverWatch uses direct in-line pumping to eliminate the need for a wet well entirely. Wastewater moves straight from the entry point to discharge without being collected in a tank. The system uses smart sensors and variable speed drives to prevent clogging and optimize operation.

It also features three impeller options to handle different types of wastewater:

- DIPCUT impeller cuts through debris with 70 percent efficiency

- Vortex impeller processes solids the same size as the pipe inlet at 50 percent efficiency

- High-efficiency impeller supports flows up to 1,500 gallons per minute with 85 percent efficiency

This flexibility reduces maintenance by as much as 80 percent and delivers major savings every year.

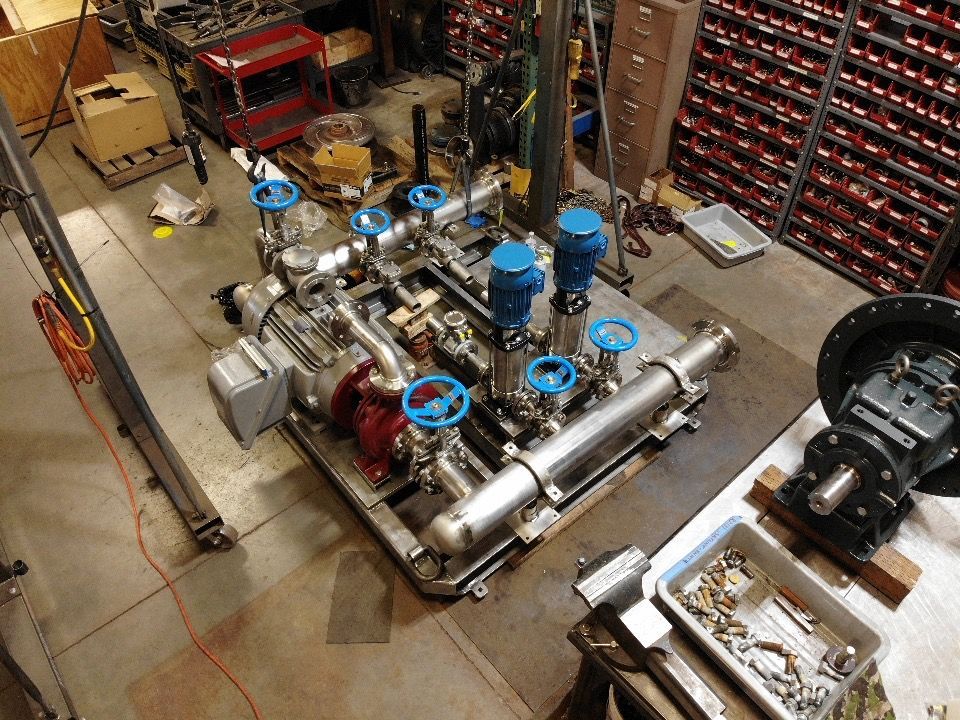

Real-World Results at City Creek Mall

One of the most compelling examples is the recent installation at City Creek Mall in Utah. Rhino Pumps replaced the outdated wet well system with a dry pit OverWatch configuration. The outcome was clear and immediate. There were no overflows, no odors, and barely any downtime. For commercial properties that rely on consistency, this is a major breakthrough.

Your Next Step

Wet well systems are outdated. OverWatch, together with Rhino Pumps, provides a smart and modern replacement that delivers better performance and safety. Whether you operate in Utah or anywhere else, the time to upgrade is now. Reach out to Rhino Pumps and find out how OverWatch can transform your wastewater system with a custom solution designed for your exact needs.