Successful Rhino Pumps OverWatch® installations

Completed by our team across the Western United States

Upcoming Rhino Pumps OverWatch® projects

Currently in engineering, fabrication, or deployment

OverWatch® systems installed across the USA

Nationwide adoption of advanced in-line wastewater pumping

Enhances Safety for Maintenance Crews & Lowers Environmental Impact.

Non-clog

Designed for Reliability. Keeps a careful watch so you don’t have to.

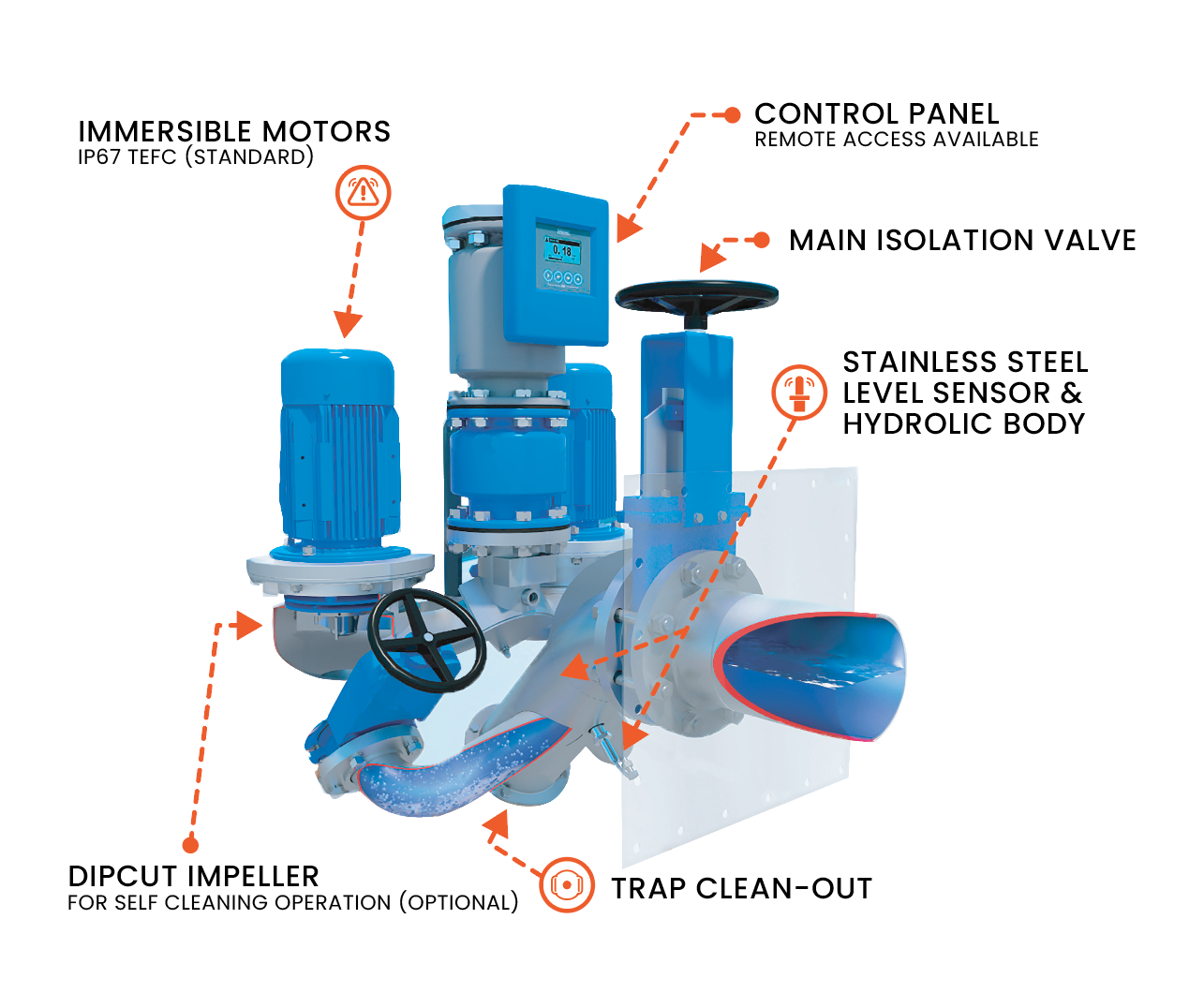

OverWatch® is a direct in-line pump system designed to completely eliminate the wet well. This breakthrough wastewater solution lifts influent at the point of entry, removing the need for deep vaults or confined spaces. It uses advanced sensors and intelligent controls to monitor pressure, flow, and system conditions in real time, improving efficiency while protecting crews from hazardous environments. OverWatch™ simplifies pump station design, reduces odors, cuts maintenance, and enhances operational safety across municipal, industrial, and commercial applications.

Completely Eliminate the Wet Well

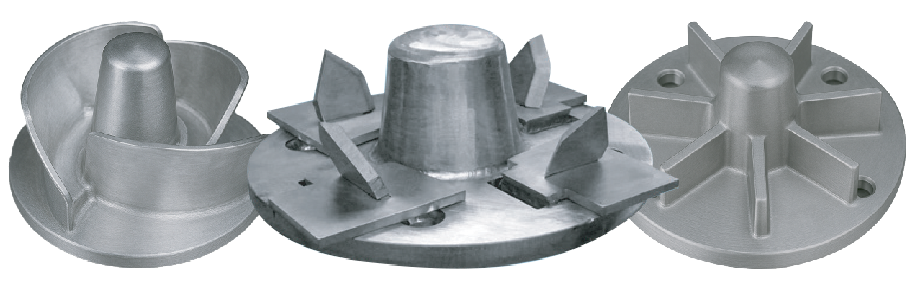

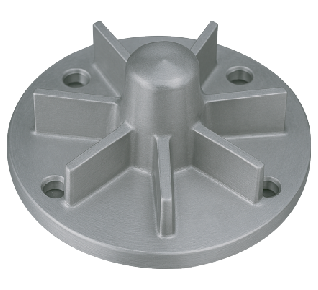

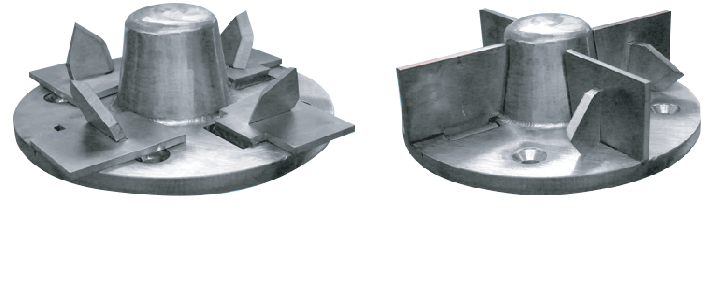

Stainless Steel Impeller Options

Vortex

- Keeps solids away.

- Cuts clogging by 60%

DipCut™

- Pumping & Shredding

- Consumes less energy

High Effeciency

- Up to 85% efficiency

- Handles 1,500 GPM

Stainless steel body designed to withstand corrosion.

- High temperature wash-down /Clean in Place (CIP)

- Fats, Oils, Greases (F.O.G.)

- Solids handling

- Acidic and caustic processing

Industrial

Municipal

Breakthrough technology lifts influent at entry.

- Sewage & solids handling

- Stormwater management

- Wastewater

- Lift / Pump stations

Commercial

Effluent is contained, eliminating odors & reducing maintenance.

- Wastewater

- Stormwater management

- Boiler condensate handling

- Solids handling

Questions & Answers

What happens if the level sensor fails?

If the level sensor stops working, the controller switches the main pump to a set speed to keep pumping. It also shows an alarm and can send a warning through the network to let someone know.

What happens if one motor stops working?

If a motor stops working and the system can’t fix it automatically, the controller sends the flow to the other pump. You can remove the broken motor without stopping the system by closing the branch valves.

Replacing the motor takes just minutes, and a cover plate comes with the system to seal the motor spot during repairs, keeping the area safe and clean.

What happens to large debris from a gravity network?

Large debris gets caught in the stone trap at the back of the housing. This trap lets heavy debris drop out of the flow, and you can remove it by hand through the service hatch. If the network often has stones or gravel, adding a trap in the upstream inspection chamber can help.

What happens if the system loses power?

When the system loses power, it’s the same as with the other system...

Pumping stops!

For critical networks, an automatic startup generator is recommended.

How does the system keep pipes clear of material buildup?

The system needs a minimum speed of 0.75 m/s (2.5 ft/sec) to flush material out of the pipes. Variable frequency controllers adjust the pump speed to match the needed flow. If there’s a blockage, the motor speeds up to clear it. The system can be fine-tuned to the right flow range to prevent solids from building up..

How can the system be customized for different wastewater needs?

Rhino Pumps designs the system to fit your specific wastewater needs. They customize the pump package with the right motors, controls, and equipment, all built into a ready-to-use skid for easy installation. This ensures the system works efficiently for your application.

Reliable Performance in the Toughest Pumping Conditions

OverWatch® has features such as real-time data analytics and automated adjustments, the OverWatch™ pump system minimizes downtime and enhances the overall reliability of pumping operations. This system is especially beneficial in environments where precision and efficiency are critical, such as in water treatment plants, chemical processing facilities, and oil and gas operations.

Serving the Southwest with OverWatch® Wastewater Solutions

OverWatch eliminates wet wells and simplifies wastewater pumping for municipalities, industries, and commercial developments across the Southwest. From the desert heat of Arizona and Nevada to the mountain climates of Utah and Idaho, OverWatch delivers reliable, maintenance friendly performance that fits each region’s unique infrastructure challenges.

Each page includes information specific to local conditions, industries, and municipalities, helping project engineers and public works directors understand how OverWatch can replace traditional wet wells with safer, smarter, and more sustainable wastewater technology.

Our engineering and field teams design, deliver, and support complete OverWatch installations throughout the region—providing consultation, factory integration, and on site startup for utilities, contractors, and private operators.

Before

After

Pre-Tested Systems

Every system is rigorously tested at our facility to ensure flawless performance on-site.

End-to-End Accountability

If there’s a problem, we’ll fix it - because we built it.

Engineered Systems Delivered Fast and Ready to Run

Our pump packages are custom engineered to your application. All fabrication, motors, controls, pumping equipment and installation is completed by Rhino Pumps experts, securing the fastest lead times in the industry. Our engineers will design a configuration that ensures efficiency and reliability in your pumping application.

Rhino Pumps stands out in the industry for superior lead times compared to other pump companies due to streamlined manufacturing processes and efficient supply chain management. We leverage advanced technology and automation in our production facilities, which allows for quicker turnaround on orders without compromising quality. Additionally, Rhino Pumps maintains strong relationships with suppliers, ensuring that necessary components are readily available, which further reduces delays. Our commitment to customer satisfaction makes Rhino Pumps a reliable choice for clients needing timely pump solutions.

Your Current Process

Motors

Electrician

Controls

Client

Engineer

Toby

Contractor

Pumps

Plumber

Your Future...

Client

Engineer

Designing pump systems involves managing information from multiple parties, creating challenges that can lead to increased costs, longer lead times, and mistakes. Factors like design, purchasing, and delivery delays often result in cost overruns that strain budgets and complicate timelines. Unclear responsibilities among stakeholders can cause confusion and inefficiency, while excessive contact points can frustrate communication. However, pumps don’t have to be complicated! Streamlining the process and enhancing collaboration can simplify pump system design and implementation, ensuring a smoother experience for all involved.

Pumps DON'T have to be this complicated!

Find Exactly What You Need

Pumps by Type

Rhino Pumps offers a wealth of leading manufacturers and products to satisfy every application. We are the preferred choice for vertical turbine pumps, booster pumps, slurry pumps, split case pumps and more.

Pumps by Industry

Serving the Mountain West with the highest quality pump brands and service for every industry; including mining, agriculture, industrial, municipal, wastewater, commercial and more.

Pump Parts

Rhino Pumps stocks most replacement pump parts for leading brand manufacturers. We carry name brand and replacement mechanical seals, pump accessories, well pump parts and more.

Pump Field Service

Our expert on-site field service crew is highly trained and specializes in pump removal and meticulous pump installation, vibration analysis, pump testing, well videos, and pump maintenance.

Pump Repair & Maintenance

Our expert pump mechanics are highly trained and the best in the industry. Our full service pump repair shop is complete with full machining, coating and fabrication capabilities.