Modular Pump Systems for Industrial Applications Why RhinoStak Is a Smart Long-Term Investment

What Is a Modular Pump System and Why Does It Matter in Industrial Applications

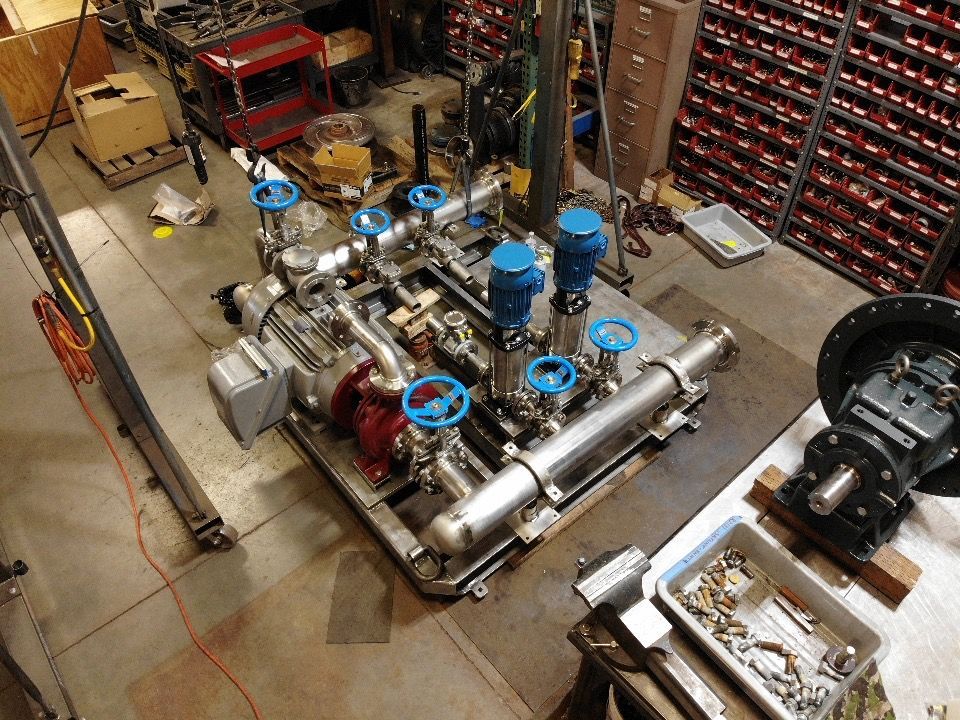

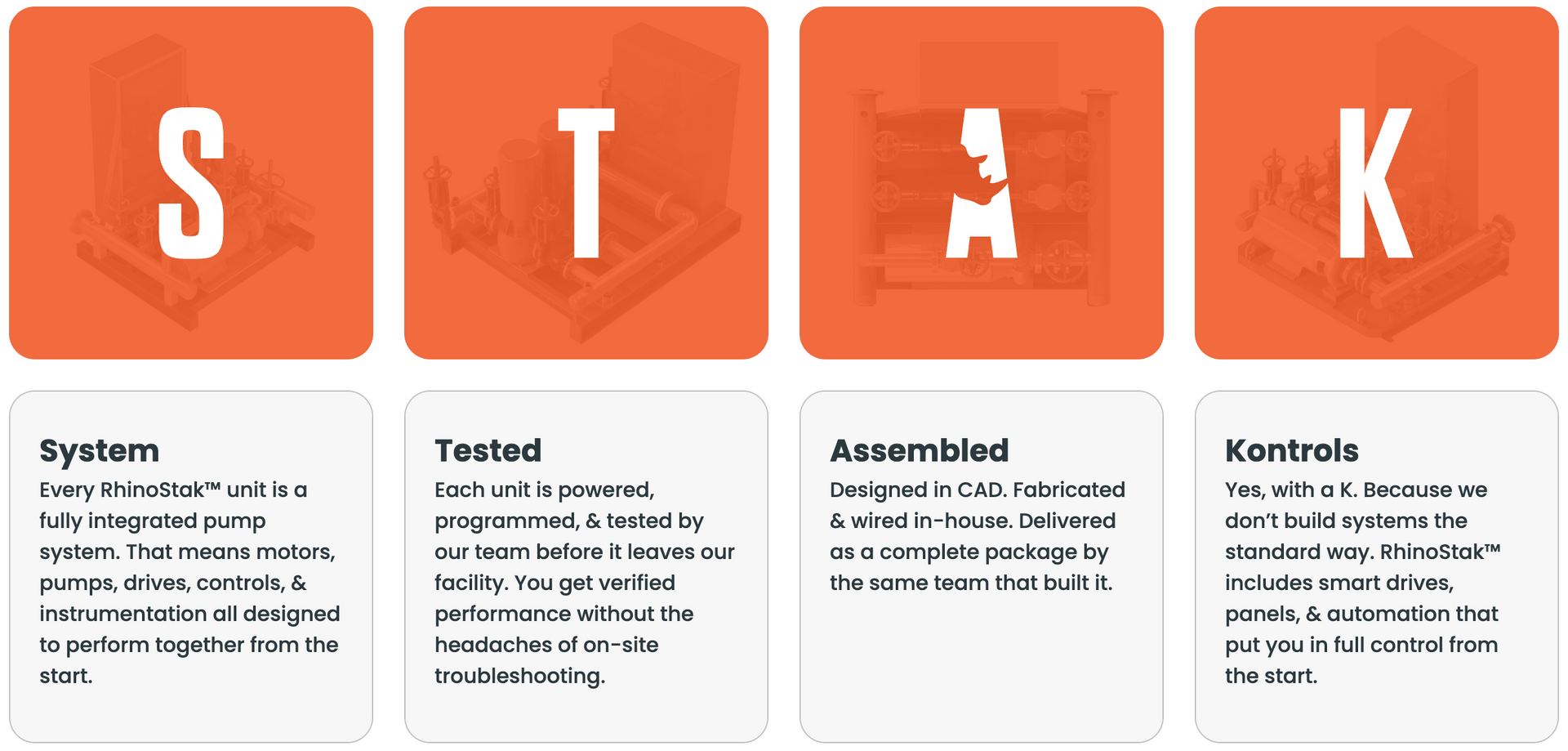

Modular pump systems — also called packaged or pre-engineered pump skids — are changing how industrial facilities design, install, and maintain large-scale water systems. Instead of building pump stations in the field with multiple contractors, a modular system like RhinoStak arrives fully assembled, factory tested, and ready to connect.

For industries dealing with high flow, aggressive fluids, or mission-critical operations, the modular approach offers real advantages in cost control, downtime reduction, and lifecycle performance

Why RhinoStak Makes Sense for Industrial Facilities

Reduced Installation Risk and Labor

Scalable Design That Grows With Your Facility

Easier Service and Predictable Maintenance

Comparing Field-Built Pump Rooms to Modular Pump Skids

| Feature | Field-Built Pump Room | RhinoStak Modular System |

|---|---|---|

| Design and Engineering | Multiple vendors and trades | Single-source design-build |

| Installation Timeline | Weeks to months | Rapid site setup |

| Factory Testing | Often none | Full hydraulic and control testing |

| Site Labor | High coordination effort | Minimal crew required |

| Expandability | Requires redesign | Modular and adaptable |

| Cost Predictability | Prone to change orders | Fixed cost from proposal to delivery |

In many cases, RhinoStak can also be paired with the OverWatch pump system — a stainless steel submersible pump with built-in VFD and smart monitoring, ideal for washdown, high-surge, or aggressive wastewater conditions.

Built for Industrial Challenges in the West and Beyond

Rhino Pumps has delivered pumping systems to sites across Utah, Arizona, Nevada, and Idaho — from food processors in Idaho Falls to mining sites in northern Arizona. With growing demand for scalable, pre-engineered infrastructure, RhinoStak is a fit for:

- Projects with tight schedules or limited labor

- Facilities with expanding water handling needs

- Plants seeking lifecycle cost savings

- Engineers aiming to standardize pumping platforms across sites

We also support clients beyond the western region — reach out to discuss availability and delivery based on your project scope.

Is a Modular Pump Skid Right for Your Industrial Application?

If you're designing a new plant, upgrading a legacy station, or trying to reduce long-term cost exposure, a RhinoStak system can help you move faster and smarter. It delivers real ROI by:

- Shortening install time

- Reducing maintenance complexity

- Offering flexibility for the future

Get Help Designing Your RhinoStak System

Rhino Pumps offers consultative design support for industrial and municipal projects. We’ll work with your engineering team to size the system, spec the components, and ship a solution that’s ready to work on day one.

Contact Rhino Pumps to request a RhinoStak consultation or learn how modular pump systems can strengthen your long-term infrastructure plan.