Harnessing Geothermal Energy in Utah How Rhino Pumps Supports the FORGE Project in Milford

What Is Geothermal Energy and How Does It Work

Geothermal energy taps into the Earth’s natural heat to produce renewable power. This heat, stored beneath the surface in hot rock formations and fluid reservoirs, can be harnessed to generate electricity or provide direct heating. Unlike solar or wind, geothermal provides consistent, around-the-clock energy without being weather-dependent.

There are several types of geothermal systems, including:

- Shallow geothermal for heating and cooling buildings

- Hydrothermal systems that use hot water from underground reservoirs

- Enhanced Geothermal Systems (EGS) — where engineered fractures allow water to circulate through hot rock, even in areas without natural reservoirs

What Is the Utah FORGE Project and Why It Matters

The Utah FORGE project (Frontier Observatory for Research in Geothermal Energy) is a U.S. Department of Energy initiative located near Milford, Utah. It is a first-of-its-kind field laboratory dedicated to advancing Enhanced Geothermal Systems.

The goal of FORGE is to demonstrate that EGS can be successfully deployed in regions without traditional hydrothermal activity — unlocking geothermal potential across the entire U.S., not just in hot zones like California or Nevada.

FORGE is drilling more than 10,000 feet into hard granite to create engineered geothermal reservoirs, where high-pressure water is injected, heated, and circulated to the surface to produce electricity.

How Pumps Make Geothermal Energy Possible

Pumps are critical to every stage of geothermal development, especially in EGS. Their roles include:

- Injecting water into hot rock formations under extreme pressure

- Circulating superheated fluid to surface systems

- Maintaining continuous high-flow rates despite challenging temperatures and depths

These systems demand

specialized high-pressure, high-volume pumps that can operate under thermal and mechanical stress without failure.

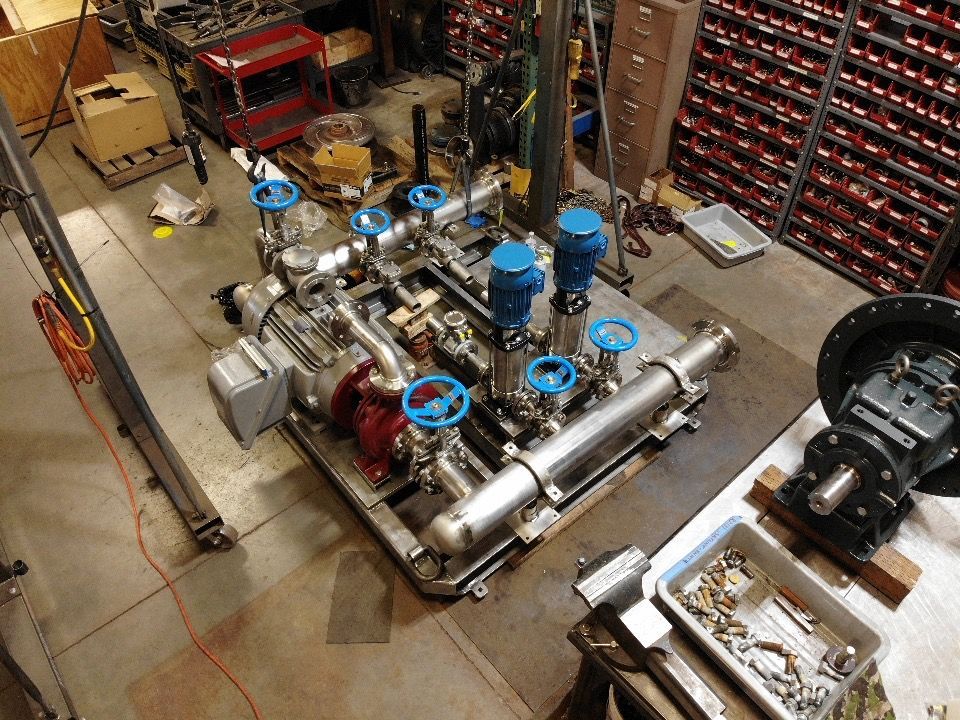

Rhino Pumps’ Role in the Utah FORGE Project

Rhino Pumps was selected to provide permanent pumping equipment for the FORGE project in Milford. Our involvement includes:

- Custom high-head pumps engineered for extreme depths and flow rates

- Materials selected for geothermal compatibility, including high-temp seals and corrosion-resistant components

- Support and service capability based in Utah, ensuring FORGE has direct access to replacement parts and technical expertise

- Partnership with Levare Pumps, contributing to advanced system integration and performance

By helping move superheated fluids efficiently through the engineered reservoir, Rhino Pumps is playing a direct role in proving the viability of enhanced geothermal energy.

Why Geothermal Energy Matters for the West

Utah, Nevada, and Idaho have enormous geothermal potential — both from hydrothermal sources and enhanced geothermal zones. As demand for carbon-free, base-load energy increases, geothermal offers a compelling solution:

- Constant energy production

- Low emissions

- Minimal land use

- Long asset life and grid stability

With projects like FORGE demonstrating what’s possible,

Rhino Pumps is positioned to support a new wave of geothermal innovation across the western U.S.

Learn More About Rhino Pumps’ Energy Capabilities

From traditional municipal water systems to advanced renewable energy projects, Rhino Pumps delivers custom-engineered pump solutions that meet the highest demands. Our work on the FORGE project is part of a broader effort to support:

- Energy independence

- Infrastructure modernization

- Regional economic growth through innovation

Contact Rhino Pumps to learn more about our role in renewable energy and how we can support your next infrastructure or energy project.