Snowmaking Pumps and Systems: What Ski Resorts Need to Know Before Winter

Why Snowmaking Pumps Are Critical for Resort Operations

As snowfall becomes less predictable, ski resorts in places like Utah, Idaho, Nevada, and Arizona are relying more on snowmaking systems. At the heart of these systems are snowmaking pumps, responsible for delivering water to snow guns at the right pressure and flow.

A well-designed pump system ensures early-season openings, slope consistency, and operational flexibility throughout winter.

Understanding the Snowmaking Process and Flow Demands

Modern snowmaking relies on pumping chilled water through snow guns that atomize it into the air. When conditions are cold enough, those droplets freeze into artificial snow.

This process requires:

- High flow rates (hundreds to thousands of gallons per minute)

- High pressures (typically 200 to 500 PSI)

- Continuous pumping during low-temperature windows (usually overnight)

Water must reach snow guns at the correct velocity and droplet size. Any pressure drop or flow loss can reduce snow quality or waste energy.

Types of Pumps Used in Snowmaking Systems

Centrifugal Pumps

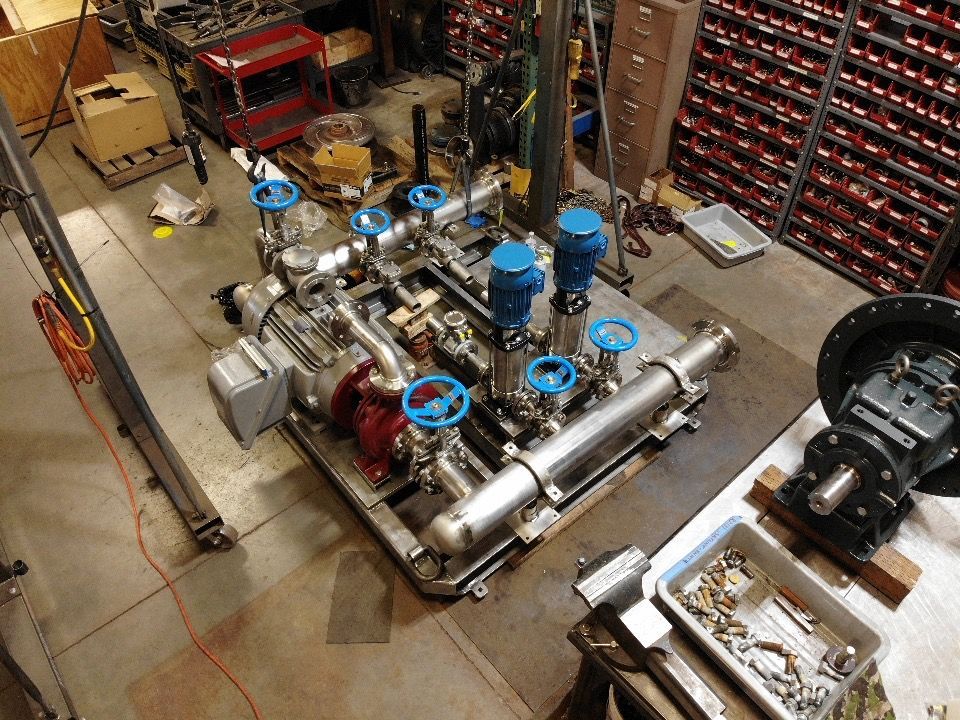

Used as base or primary supply pumps, these move large volumes of water from holding ponds or reservoirs to booster stations. Rhino Pumps engineers centrifugal systems for optimal flow with minimal maintenance in harsh winter settings.

Multistage Booster Pumps

These pumps pressurize the water for final delivery to the snow guns. High head, compact, and efficient, they are critical for overcoming elevation gain and long-distance pipe friction.

Submersible Intake Pumps

In colder regions, especially in Idaho and Utah, submersibles are used to prevent freezing by operating below the ice line. They also provide quiet and reliable startup even in remote reservoirs.

Key Factors When Designing Snowmaking Pump Systems

Designing a reliable snowmaking system involves:

- System Curves and Elevation Losses: Calculate pressure and flow at every lift, slope, and snow gun.

- Cold-Weather Durability: Use materials like stainless steel, bronze, or rubber-lined casing for freeze resistance.

- Vibration and Flow Control: Pumps must withstand surge during variable demand or sudden valve closures.

Rhino Pumps works with ski resorts in Utah, Arizona, and Idaho to custom-build snowmaking pump packages that match terrain profiles and temperature ranges.

Maintenance Planning Before the First Snowfall

Preventive maintenance before the first freeze is critical. Recommendations include:

- Flushing and inspecting impellers and casings for off-season corrosion

- Verifying motor alignment, seal condition, and flow rates

- Testing control panels, VFDs, and remote sensor systems

- Protecting exposed pumps with insulation jackets or enclosures

Rhino Pumps Supports Mountain and Resort Operations

Rhino Pumps has years of experience supporting ski resorts across the western U.S. with engineered pump systems tailored to winter needs.

We offer:

- High-pressure centrifugal and booster pumps for snowmaking

- Freeze-resistant designs and enclosures

- Preventive maintenance plans for winter startup

- Custom controls and monitoring for remote ski runs

Contact Rhino Pumps to get your snowmaking system ready for the season.