Vertical Pump Installation and Startup: What to Know Before You Begin

Why Proper Vertical Pump Installation Matters

Vertical pumps, particularly vertical turbine pumps, are integral to applications such as deep well irrigation, municipal water systems, and industrial processes. Correct installation is crucial to ensure optimal performance, longevity, and safety. Improper setup can lead to issues like misalignment, excessive vibration, and premature wear.For comprehensive guidelines, refer to the National Pump Company's installation manual.

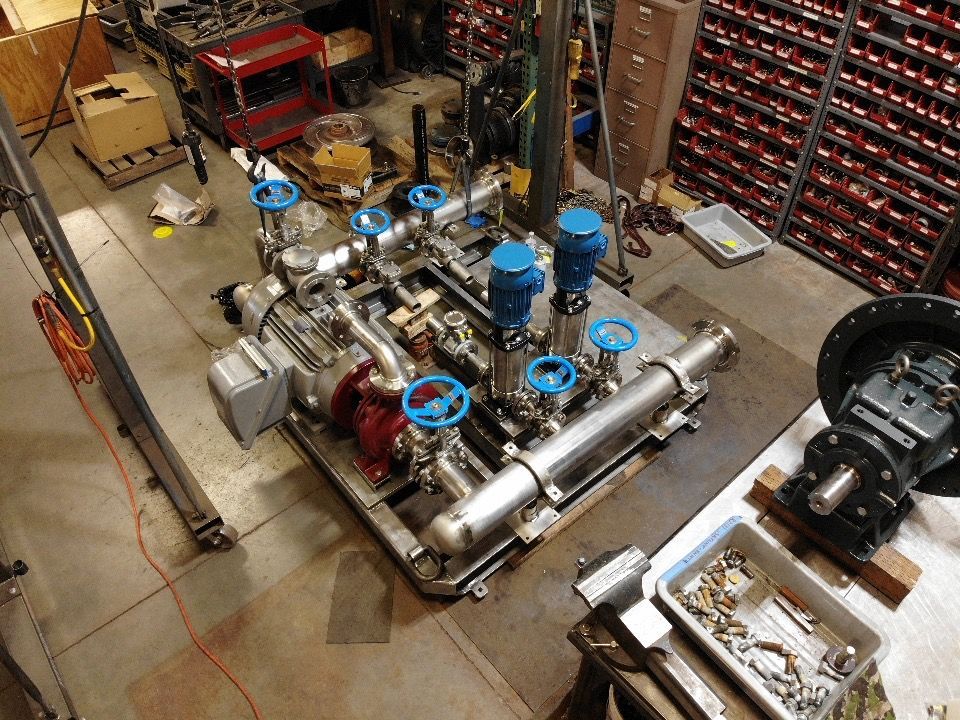

Key Components in Vertical Pump Installation

Foundation and Baseplate

A stable and level foundation is essential. The baseplate should be securely grouted and shimmed to ensure vertical alignment. Uneven foundations can cause shaft binding and operational inefficiencies.

Column Assembly and Pump Bowl

During assembly, handle the pump column and bowl with care to prevent stress on the shaft. Ensure that column sections are properly torqued and lubricated. The pump bowl should be submerged to the correct depth to meet Net Positive Suction Head (NPSH) requirements, preventing cavitation.

Shaft Alignment and Tensioning

Ensuring Proper Shaft Alignment

Accurate alignment between the pump shaft and motor is vital. Misalignment can lead to increased wear and energy consumption. Utilize precision tools like dial indicators or laser alignment systems for best results.

Correct Shaft Tensioning

Proper shaft tension prevents issues such as excessive vibration and bearing overload. Follow manufacturer specifications for tensioning values.

Priming and Pre-Startup Checks

Before initiating startup, ensure the pump is properly primed:

- Fill the pump column to eliminate air pockets.

- Verify the rotation direction by momentarily starting the motor.

- Check that the lubrication system is functioning correctly.

- Confirm that all valves are in the appropriate positions.

Monitoring During Initial Startup

During the first startup, closely monitor the following:

- Listen for unusual noises or vibrations.

- Observe shaft movement and thermal expansion.

- Monitor electrical parameters such as current and voltage.

- Ensure that flow and pressure readings align with expected values.

- Inspect for leaks around seals and packing.

Rhino Pumps' Expertise in Vertical Pump Services

Rhino Pumps specializes in providing comprehensive solutions for vertical pump systems. Our services include:

- Supplying and fabricating vertical turbine pumps tailored to specific applications.

- Offering pre-installation alignment and training services.

- Providing on-site assistance for shaft tensioning and startup procedures.

- Delivering troubleshooting support and performance optimization.

Contact Rhino Pumps to discuss your vertical pump installation and startup needs.