Pump Cavitation Explained and How to Prevent Costly Damage

What Is Pump Cavitation and Why It Should Be Taken Seriously

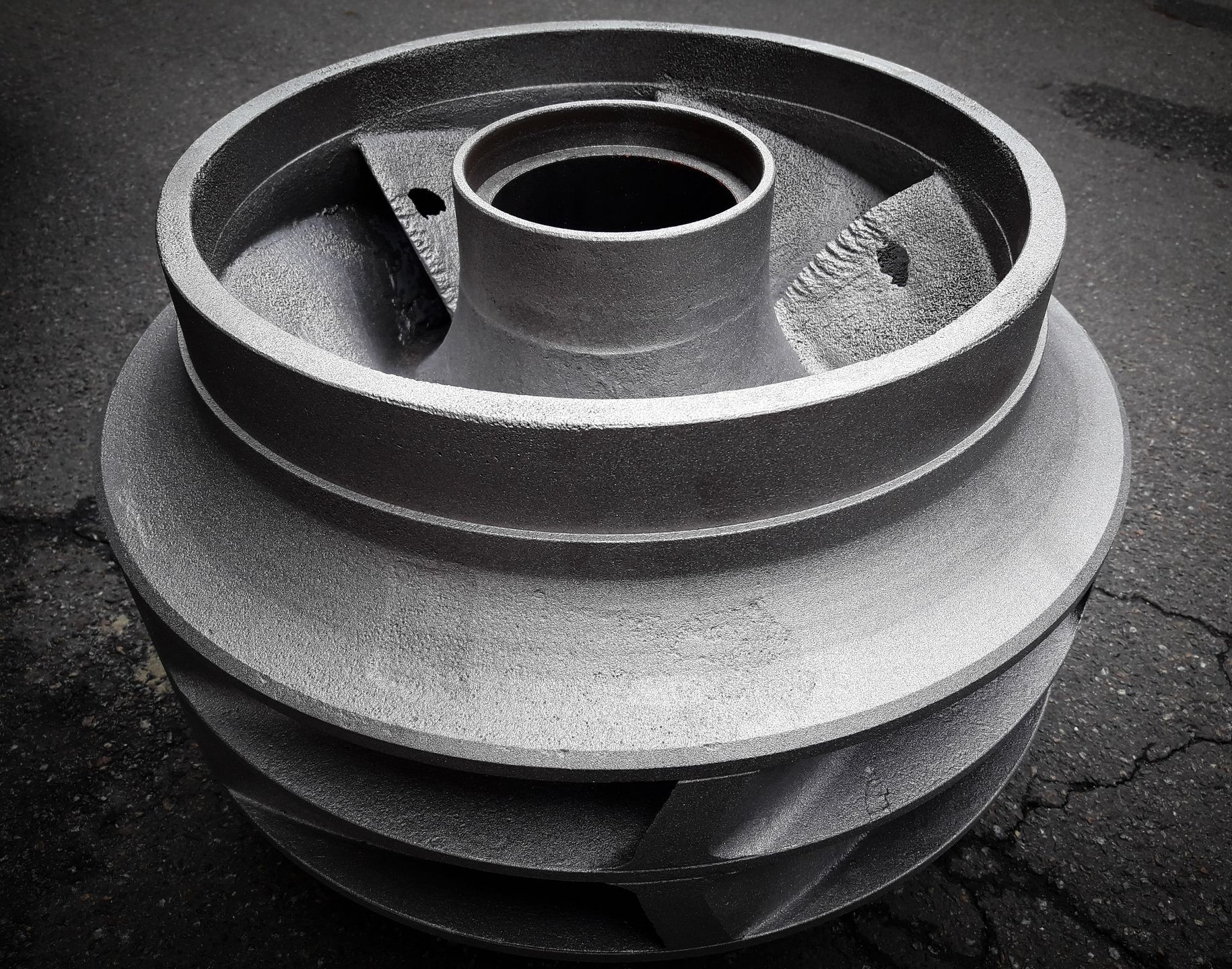

Pump cavitation occurs when vapor bubbles form in the liquid inside a pump due to low pressure and then collapse violently. These micro-explosions create shockwaves that chip away at impellers, reduce efficiency, and eventually destroy the pump.

Whether you manage a wastewater system in Utah or operate mining equipment in Nevada, ignoring cavitation leads to:

- Eroded impeller surfaces

- Excess vibration and seal failure

- Sudden downtime and expensive rebuilds

Cavitation isn’t just noise. It’s a sign of hydraulic imbalance.

What Causes Cavitation in Pump Systems?

Cavitation is caused when net positive suction head available (NPSHa) drops below the net positive suction head required (NPSHr). This means your pump isn’t getting enough pressure at the inlet to keep the fluid in a liquid state.

Common culprits include:

Poor Suction Piping Design

Long pipe runs, elbows near the pump, or undersized lines reduce NPSHa. These errors are often seen in older municipal systems or space-constrained pump rooms.

High Fluid Temperatures

Warmer liquids vaporize at lower pressures, increasing the risk of cavitation. This is common in geothermal water systems across Utah and Idaho.

Excessive Pump Speed

Operating the pump above its design point increases turbulence and suction pressure drop. This often happens when variable frequency drives are misconfigured.

How to Identify the Signs of Cavitation

Catch cavitation early with these telltale signs:

- Popping or grinding noises — like gravel inside the pump

- Drop in flow or pressure — even when the pump seems to be running

- Vibration or mechanical looseness — often misdiagnosed as imbalance

- Pitting or erosion on impellers and casing after inspection

Best Practices to Prevent Pump Cavitation

Prevention starts at the system level. Use these proven strategies:

Improve Suction Conditions

- Use shorter suction pipe runs

- Install straight sections before the inlet

- Position the pump below the fluid source when possible

Lower Pump Speed or Adjust VFD

Reducing pump speed reduces pressure drop and gives the fluid more time to stay in liquid form. Work with a qualified technician to tune VFDs properly.

Select a Better Suction Head Design

Use impellers with low NPSHr or switch to pumps designed for low inlet pressure. Vertical turbine and self priming models offer good alternatives in low lift applications.

When to Call in a Cavitation Expert

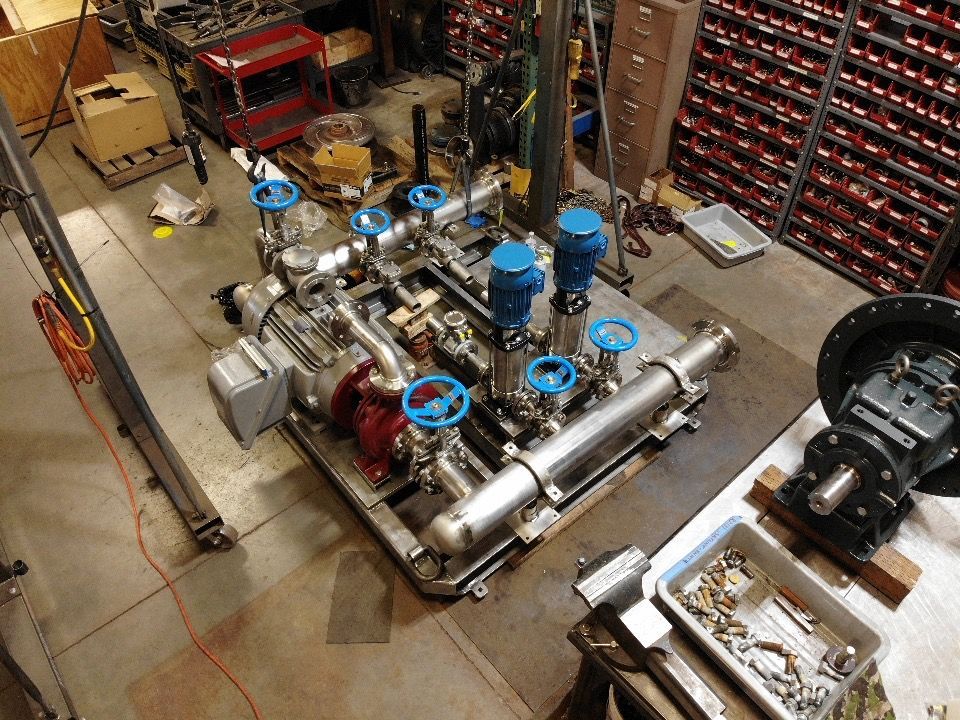

If you're unsure whether your system is experiencing cavitation or simply running inefficiently, Rhino Pumps can help. Our team serves industrial and municipal customers across Utah, Arizona, Nevada, and Idaho with:

- Onsite pump inspection and performance audits

- System curve evaluations to identify suction issues

- Impeller, seal, and casing replacements

- New pump selection with verified NPSHr margins

Contact Rhino Pumps for cavitation troubleshooting and long term pump reliability.