RhinoStak vs Duplex Pumping Stations Modular Solutions for Smarter Pumping

Why Duplex Pumping Stations Are Being Rethought

Duplex pumping stations, which use two alternating pumps in a wet well, have long been the standard in municipal and light industrial water systems. While functional, they come with notable challenges.

- Extended installation and coordination timelines

- Limited flexibility for future expansion

- Frequent electrical and control panel issues

- Increased maintenance costs and risk of system failure

As infrastructure demands evolve and labor becomes harder to source, organizations are looking for smarter, faster, and more adaptable alternatives.

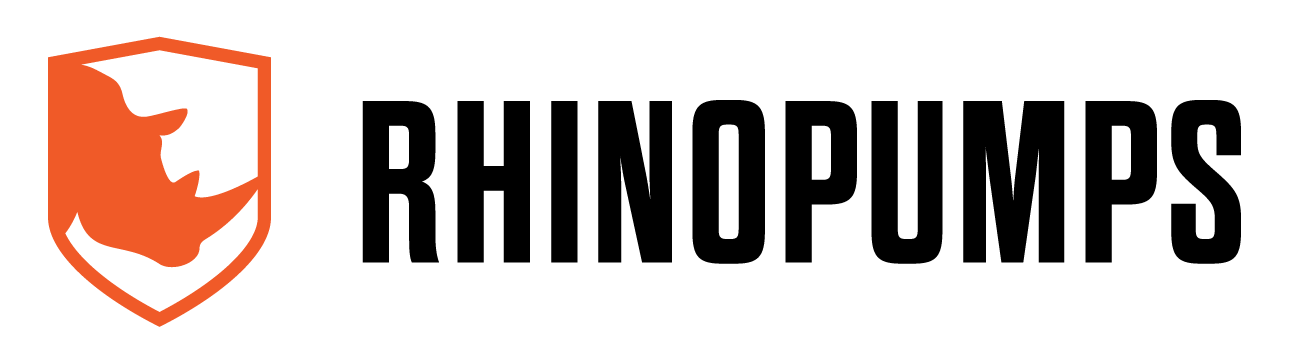

Meet RhinoStak A Modular Alternative to Traditional Pump Stations

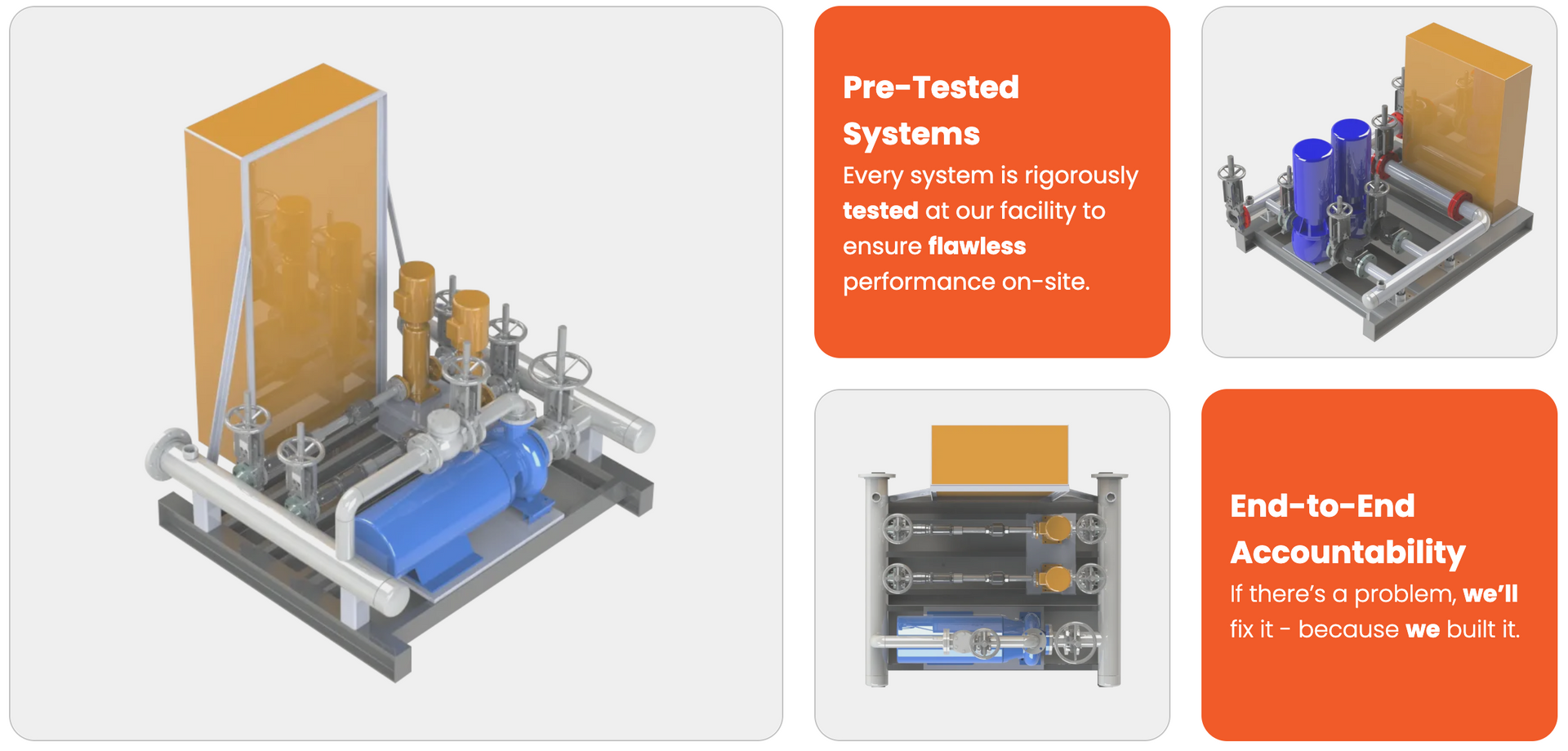

RhinoStak is a pre-engineered, fully assembled pump system designed to outperform conventional duplex configurations. It simplifies installation and future upgrades with:

- Integrated pumps, piping, valves, and controls

- Configurable layouts supporting up to six pumps

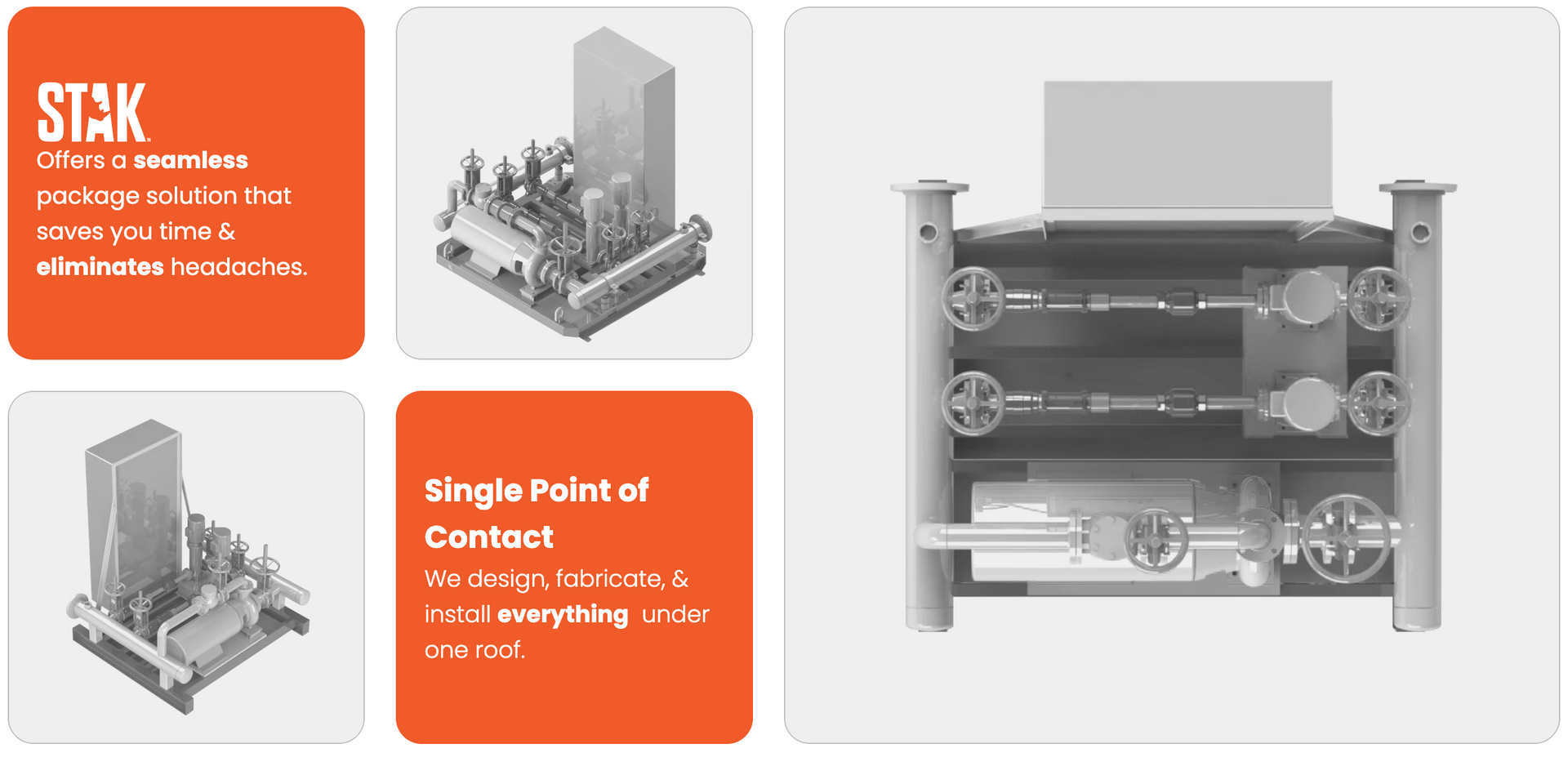

- Factory testing for performance and system integrity

- Compact, skid-mounted construction that reduces on-site work

This packaged design minimizes field labor, lowers installation complexity, and enables faster deployment.

How RhinoStak Compares to Traditional Duplex Stations

| Feature | Duplex Station | RhinoStak System |

|---|---|---|

| Installation Process | Requires excavation, vault setup, and field wiring | Delivered preassembled for fast deployments |

| Scalability | Limited to 2 pumps | Modular: Add pumps or reconfigure layout |

| Control Integration | Requires panel wiring onsite | Fully integrated and tested at factory |

| Failure Recovery | Manual pump swap or bypass | Built-in redundancy with intelligent controls |

| System Footprint | Large vault or wet well | Skid-mounted and space efficient |

In addition to the pump skid itself, RhinoStak can be paired with the OverWatch pump system, which eliminates the need for a traditional wet well. By removing below-grade collection points, OverWatch prevents the buildup of harmful hydrogen sulfide gas, improves worker safety, and greatly reduces odor concerns. The system is also designed to pass clogs and rags with ease, making it ideal for handling the toughest wastewater conditions.

Applications Where RhinoStak Is a Smarter Fit

RhinoStak systems are a great fit for both public and private applications:

Municipal Lift Station Replacements

RhinoStak allows cities to replace old duplex stations with above-ground, fully integrated systems that improve safety, reduce confined space entry, and simplify maintenance.

Industrial and Commercial Water Systems

Facilities requiring high-flow transfer, booster pressure, or dedicated washdown systems benefit from a preconfigured pump package that reduces downtime and delivers clean integration.

Emergency or Temporary Installations

Thanks to its packaged form and reduced install complexity, RhinoStak is well-suited for rapid deployment when system failure or urgent upgrades are required.

Why Modular Pumping Systems Are the Future of Infrastructure

Across the U.S., municipalities and industrial planners are turning to modular pumping systems to meet tight project schedules and reduce long-term maintenance burdens. RhinoStak offers:

- Reduced need for field coordination

- Streamlined approvals and submittals

- Predictable performance and factory validation

- Long-term adaptability for system changes or expansions

Rather than sticking with rigid, site-built pump rooms, modern infrastructure is shifting toward scalable, pre-engineered solutions.

Partner With Rhino Pumps to Build Smarter

Rhino Pumps provides RhinoStak systems tailored to your facility’s hydraulic and electrical needs. Each package is designed with integration, serviceability, and long-term performance in mind. Whether you're replacing a duplex station or planning a new build, our team can help you design and configure a smarter solution.

Contact Rhino Pumps to request a RhinoStak consultation or explore design options for your facility.