Geothermal Pumps

Rhino Pumps delivers engineered geothermal pump systems built for high temperature and corrosive fluids in energy and geothermal applications.

Engineered Geothermal Pump Solutions for High Temperature and Corrosive Environments

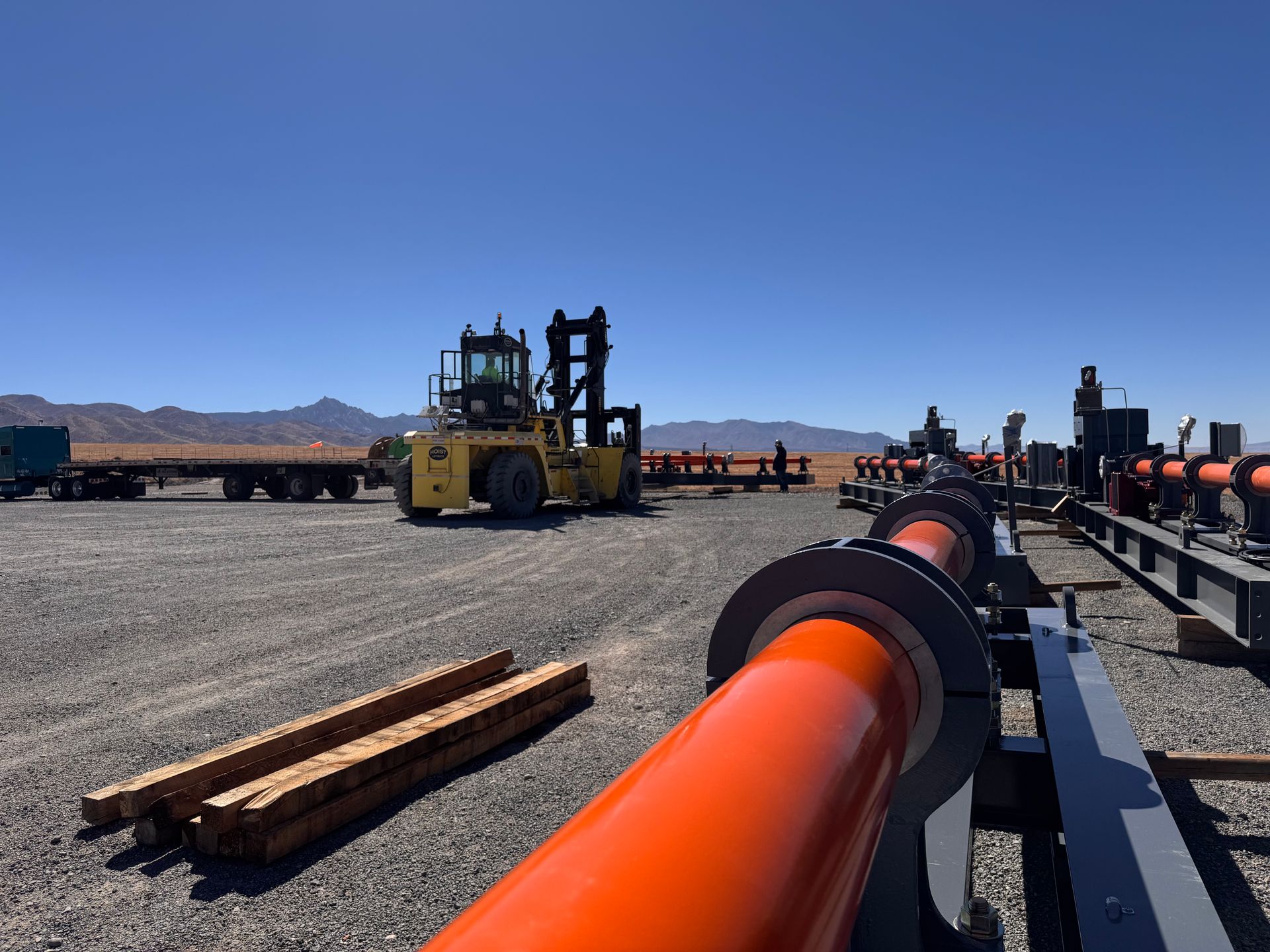

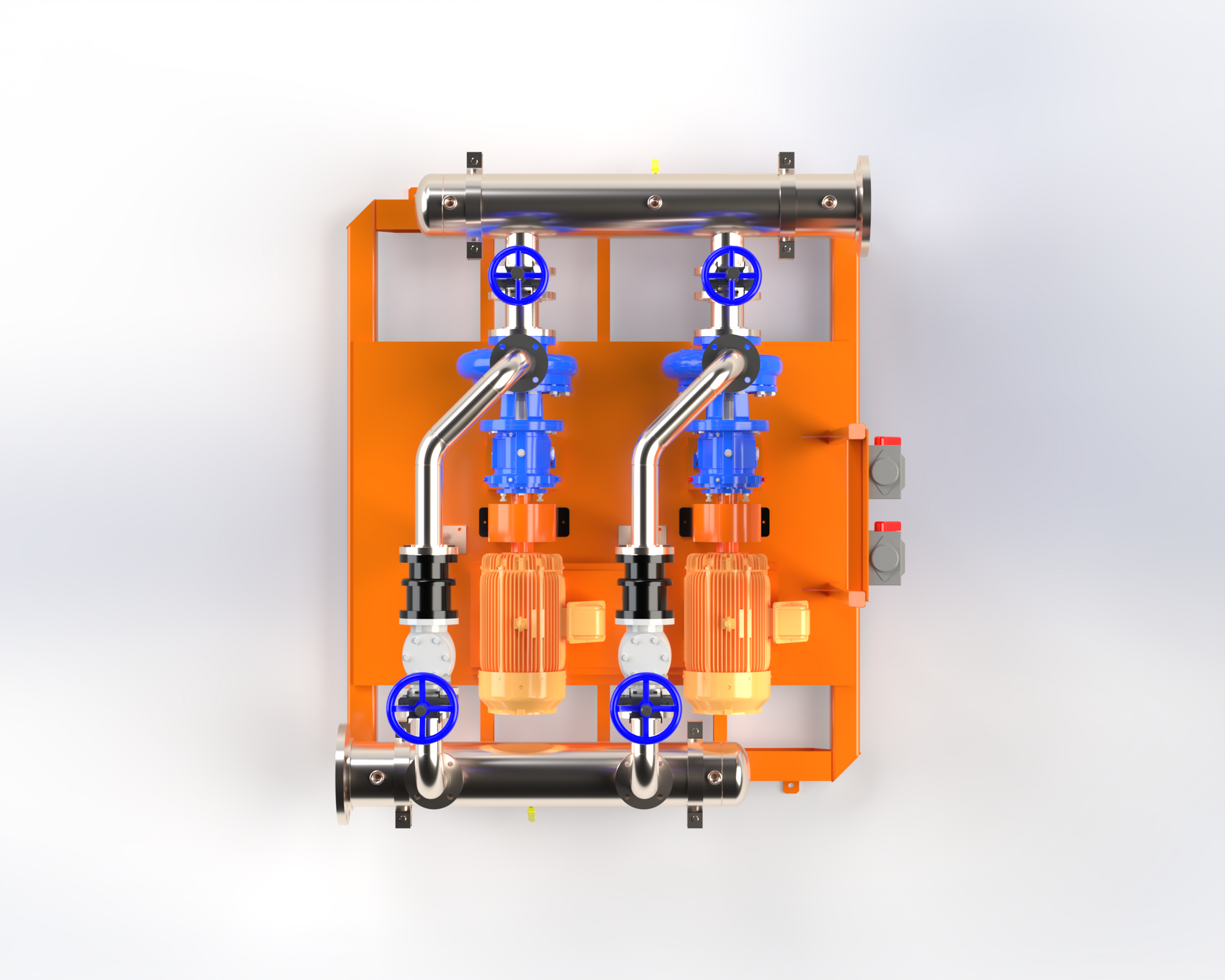

Rhino Pumps provides engineered geothermal pump systems designed to meet the extreme demands of high temperature, mineral rich fluids found in geothermal power production, reinjection wells, heat exchange loops, and energy research facilities. Our systems are built for reliability, continuous duty, and long term operation in conditions that challenge conventional pumps, with materials and configurations chosen to match each unique application.

High Temperature Geothermal Pump Systems

Rhino Pumps offers high temperature capable pumping solutions engineered specifically for geothermal energy applications, including production well fluid transfer, reinjection pumping, and heat transfer systems. These pump systems are ideal for commercial geothermal power plants, distributed energy facilities, and pilot research projects where performance, reliability, and materials compatibility are crucial.

Engineered Solutions for Harsh Fluid Chemistry

Geothermal fluids often contain high dissolved solids, corrosive minerals, and variable temperatures that accelerate wear and corrosion on standard pumping equipment. Rhino Pumps engineers geothermal systems using corrosion resistant materials such as duplex stainless steels, high alloy metallurgy, and specialized coatings. This ensures long component life, high uptime, and reduced long term maintenance demands.

Designed for Continuous Operation and Remote Sites

Geothermal facilities often run uninterrupted for long periods and can be located in remote regions. Rhino Pumps builds systems with easy access for maintenance, redundancy options for critical duty, and controls integration to support unattended or automated operation. Our packaged systems reduce field installation time and simplify commissioning.

Controls and Protection for Geothermal Systems

Precise control is essential for protecting geothermal equipment from thermal shock, cavitation, and flow instability. Rhino Pumps integrates instrumentation and controls tailored to geothermal service, ensuring safe startups, stable operation, and integration with plant level control systems. These designs support PLC and SCADA platforms common in energy production.

Supporting Geothermal Projects Across the Western U.S.

Rhino Pumps supports geothermal energy projects throughout the western United States—including Utah, Nevada, Idaho, California, and New Mexico—bringing engineered pump systems that excel in high temperature and corrosive services. Our deep application expertise and fast lead times make us a go-to partner for both commercial geothermal developers and research organizations.

Find Exactly What You Need

Pump Sales

Rhino Pumps offers reliable geothermal pump systems from trusted manufacturers and custom engineered solutions built for your specific duty point and fluid conditions.

Pump Engineering and Design

Our engineers work directly with your team to select appropriate materials and equipment to withstand the unique challenges of geothermal fluids and temperatures.

Pump & System Services

From installation support to maintenance, controls integration, and performance verification, we provide full lifecycle support for your geothermal pump systems.

Rhino Pumps Sells and Services Pumps, Pump Systems, Pump Parts and Motors in the Mountain West Region; Utah, Nevada, Idaho, Wyoming and Arizona.

Pump Products

Mine Dewatering

Priming Pumps

Sludge Pumps

Slurry Pumps

Magnetic Drive Pumps

Submersible Slurry Pumps

Lobe Slurry Pumps

Centrifugal Slurry Pumps

Vertical Turbines

Trash Pumps

Applications

Geothermal fluid production well pumping

Reinjection flow systems

Heat exchange circulation

Cooling water circulation in energy plants

Research and pilot geothermal projects across diverse terrain

Rhino Pumps Expertise

Fast Lead Times

High Temperature and Corrosion Resistant Systems

Custom Engineered Pump Solutions

Controls and Instrumentation Integration

On-Site Field Services

Fabrication, Machining, and Assembly Support