Aftermarket and ANSI Pump Parts: What They Are and When to Use Them

Introduction to Aftermarket and ANSI Pump Parts

Choosing the right replacement parts is critical to reducing pump maintenance costs and avoiding downtime. Aftermarket and ANSI pump parts offer cost-effective alternatives to OEM components, especially for ANSI-standard pump systems used in municipal, industrial, and processing applications.

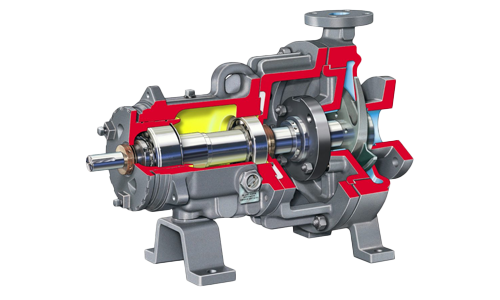

Understanding Aftermarket Pump Parts

What Are Aftermarket Pump Parts?

Aftermarket pump parts are non-OEM components manufactured to fit and function like original parts. They're widely used for pump repairs, rebuilds, and proactive maintenance, offering greater availability and reduced cost.

ANSI vs Non-ANSI Pump Components

ANSI parts are made to standard dimensions as defined by the American National Standards Institute (e.g., ANSI B73.1), making them interchangeable across brands. Non-ANSI parts are custom-sized and may require matching only with OEM models, reducing flexibility.

Benefits of Using Aftermarket and ANSI-Compliant Components

Lower Cost and Shorter Lead Times

Aftermarket and ANSI-compatible parts are often significantly less expensive than OEM parts and available on shorter notice — a major advantage when downtime is critical.

Interchangeability and Industry Compliance

ANSI standardization ensures dimensional compatibility between manufacturers, making it easier to find high-quality replacements and keep inventory simple. It also supports long-term system adaptability and rebuild efficiency.

Common Pump Parts Replaced With Aftermarket or ANSI Options

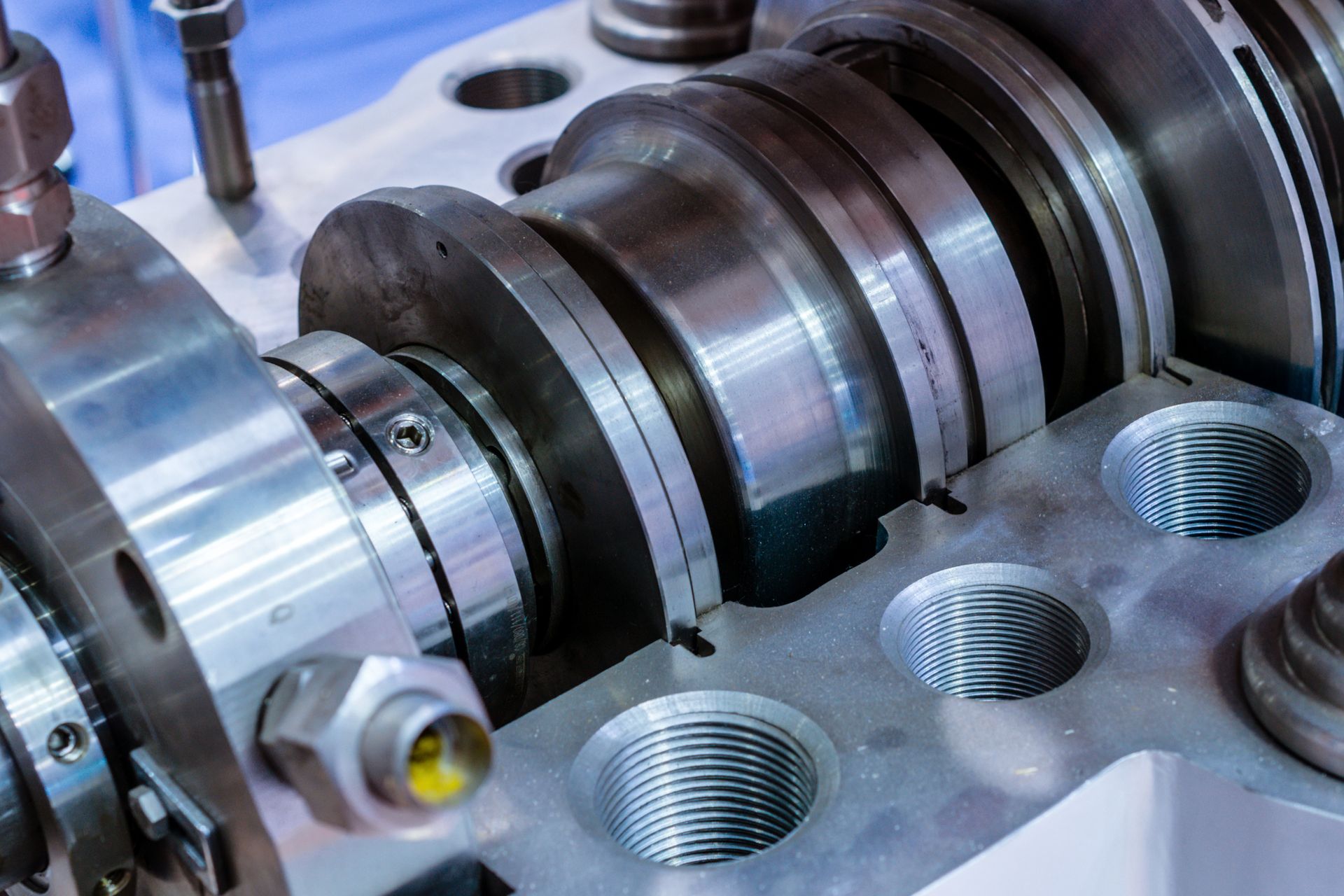

Impellers, Wear Rings, Seals, Bearings, and Volutes

These are the most frequently replaced components in centrifugal pump systems:

- Impellers: Replaced to restore performance after erosion or corrosion

- Wear Rings: Maintain efficiency by reducing internal recirculation

- Mechanical Seals: Critical to stopping leakage

- Bearings: Prevent misalignment and shaft failure

- Volutes/Casings: Often relined or repaired rather than fully replaced

Each of these can be sourced as an aftermarket or ANSI-compatible part — but only when the application permits and quality assurance is verified.

Risks and Considerations When Using Aftermarket Pump Parts

Choose High-Quality Suppliers Only

Aftermarket parts vary widely in quality. Work only with proven suppliers who can demonstrate manufacturing precision, metallurgy standards, and part traceability.

Know When OEM Parts Are Required

In regulated systems, high-pressure zones, or when OEM warranties are still in effect, using original components may be required. Always weigh long-term performance risks against short-term cost savings.

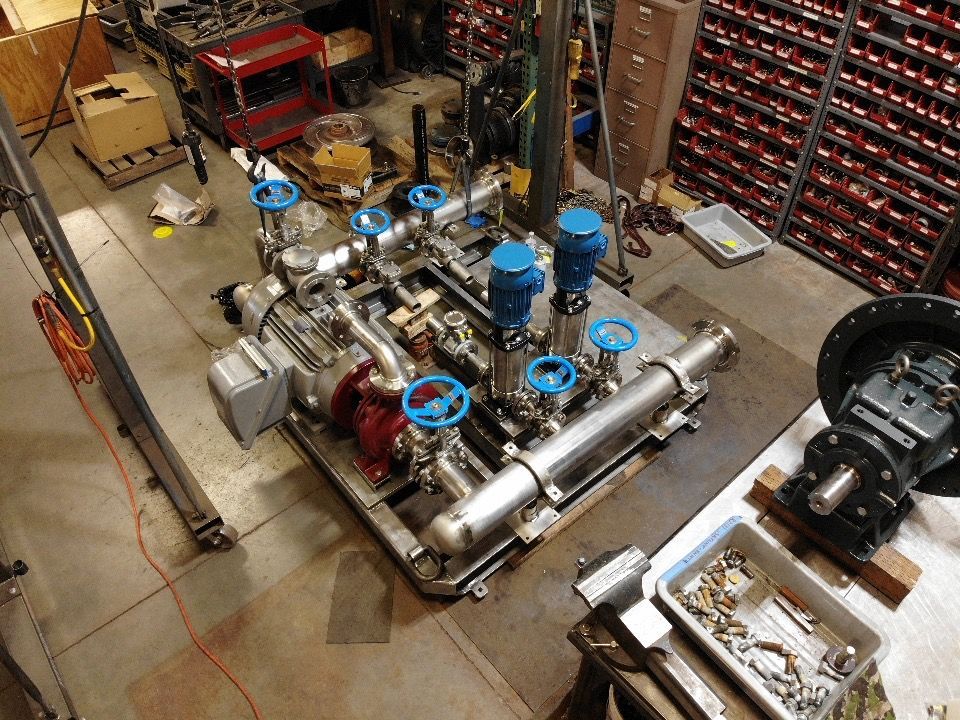

How Rhino Pumps Supports Aftermarket and ANSI-Compatible Pump Parts

Rhino Pumps helps you maintain reliability and reduce downtime with:

- Sourcing of ANSI and high-quality aftermarket parts

- Precision fitment and engineering support

- Pump rebuild and performance testing services

- Access to impellers, liners, casings, and mechanical seals

Whether you're running a standard ANSI B73.1 pump or a specialized industrial unit, we’ll help you reduce maintenance costs without sacrificing performance.

Contact Rhino Pumps to get a quote or schedule a consultation for your replacement parts or rebuild needs.