How to Size an Industrial Pump

Sizing a pump correctly ensures reliable operation, reduces energy waste, minimizes wear, and prevents costly downtime . This guide walks through industry-proven methods and standards to size a centrifugal pump accurately.

1. Gather Required Data

Flow rate (Q): Expressed in GPM or m³/h, this is typically defined during process design or calculated from a flow balance. Total dynamic head (TDH): TDH is the sum of static lift and friction losses throughout the system. Fluid properties: Includes density and viscosity. If viscosity exceeds around 2 cP, correction factors are necessary. Net positive suction head available (NPSHa): Must exceed the pump’s required NPSHr to prevent cavitation.

2. Calculate Total Dynamic Head (TDH)

Use this formula:

TDH = static head + friction head

- Static head: The vertical difference between fluid source and discharge point.

- Friction head: Calculated via pipe charts or software. Friction loss increases with the square of flow velocity, so accurate piping layouts are essential.

3. Determine NPSHa

Use this formula:

NPSHa = (atmospheric head) ± (static suction lift or head) - friction loss - vapor pressure head

- Most standards recommend that NPSHa exceeds NPSHr by at least 0.5 meters (1.6 feet) or 10–20 percent, with more margin for critical services.

- Ensure equipment is sized for worst-case conditions such as seasonal temperature changes or fluctuating fluid levels.

4. Select Pump Type

Choose between:

- Centrifugal (rotodynamic): Best for clean liquids under moderate viscosity, where flow varies with pressure.

- Positive displacement: Ideal for high-viscosity fluids or constant-rate delivery needs.

5. Use Manufacturer Pump Curves

- Generate a system curve by plotting flow versus head.

- Overlay it with the pump performance curve to find the operating point. Choose a pump that operates near its Best Efficiency Point (BEP) for optimal performance.

- Confirm that NPSHa exceeds NPSHr at the selected flow rate to prevent cavitation.

6. Adjust for Fluid Properties and Operating Conditions

- Viscosity: Apply Hydraulic Institute correction factors if fluid viscosity is greater than 2 cP.

- Affinity laws: Use these to scale performance values for different speeds or impeller trims.

7. Confirm Driver Power and Installation

- Calculate the required driver power using flow rate, total dynamic head, and pump efficiency.

- Follow ANSI/HI guidelines for installation, including proper alignment, suction piping, and support structures.

8. Best Practices Checklist

- Calculate total dynamic head (TDH) accurately

- Ensure an adequate NPSH margin (NPSHa > NPSHr)

- Select a pump that operates near its Best Efficiency Point (BEP)

- Apply viscosity correction factors for fluids over 2 cP

- Confirm driver power based on system head and pump efficiency

- Follow ANSI/HI standards for installation and alignment

- Size suction piping properly to avoid turbulence or air entrainment

- Validate system curve with actual process conditions

- Recheck all parameters under worst-case operating scenarios

- Use manufacturer pump curves to match your system exactly

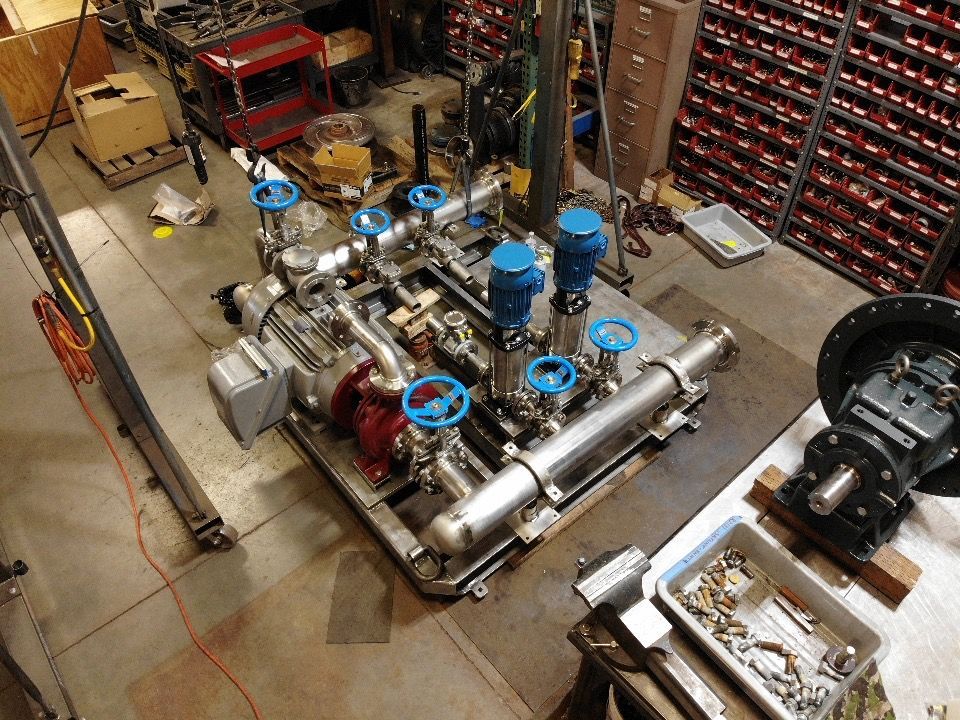

Rhino Pumps offers engineered pump sizing services based on your exact application. We use proven methods to evaluate system curves, verify NPSH, assess viscosity impact, and select the right pump from our catalog.

Contact us today for a quote or download our pump sizing form to get started.