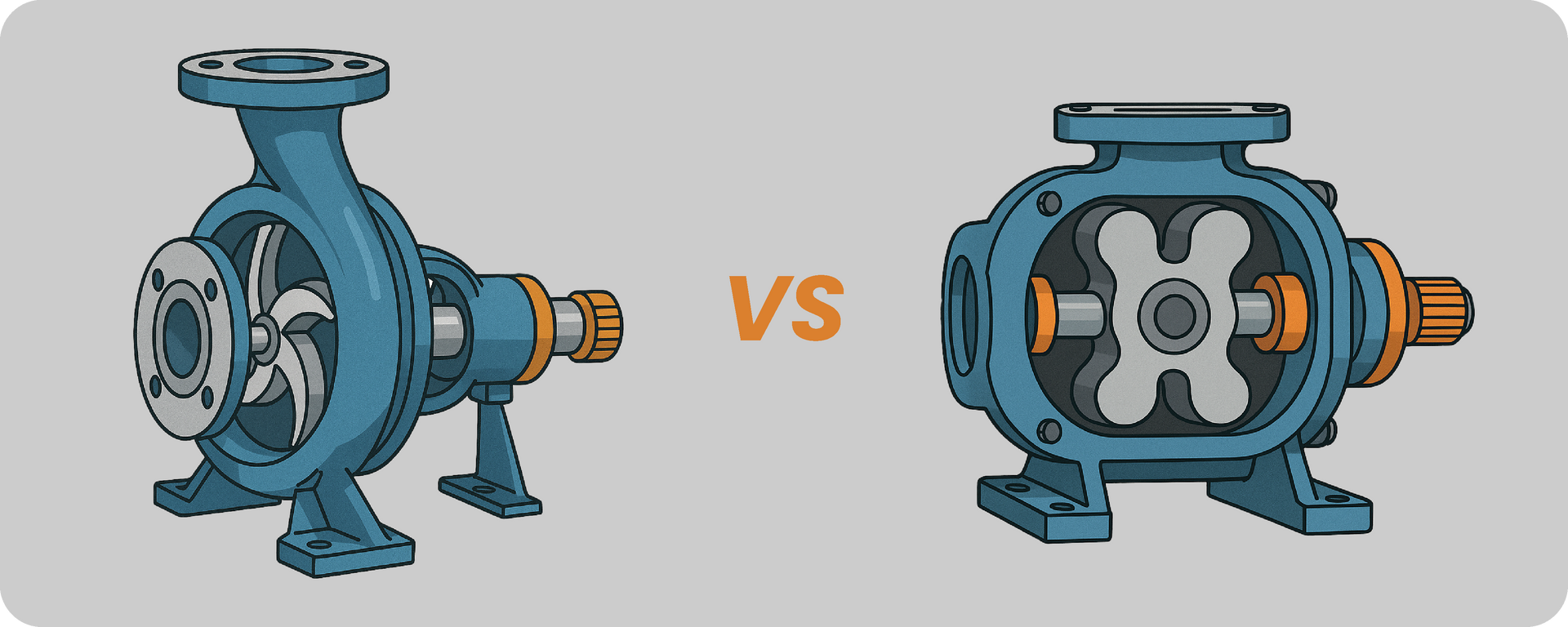

Centrifugal vs. Positive Displacement Pumps: Key Differences and Applications

Selecting the right pump is critical to achieving optimal performance, efficiency, and reliability in any system.

The two most common pump types — centrifugal and positive displacement — operate on very different principles and are suited to different applications. In this article, we break down how each works, when to use them, and what to watch out for.

If you're just getting started with a new system, be sure to also review our Complete Guide to Sizing an Industrial Pump.

What Is a Centrifugal Pump?

Centrifugal pumps use a rotating impeller to create velocity and move fluid. As the fluid enters the eye of the impeller, it is accelerated outward by centrifugal force and then converted into pressure energy. These pumps are ideal for high-flow, low-viscosity applications where pressure needs are moderate and flow can vary.

Common uses include:

- Municipal water systems

- Irrigation

- HVAC circulation

- General fluid transfer

What Is a Positive Displacement Pump?

Positive displacement (PD) pumps move fluid by trapping a fixed volume and forcing it through the discharge piping. Unlike centrifugal pumps, PD pumps deliver a constant flow rate regardless of system pressure. They are ideal for viscous, shear-sensitive, or high-pressure applications.

Common PD pump types include:

- Gear pumps

- Piston pumps

- Diaphragm pumps

Typical applications:

- Oil and gas transfer

- Food and beverage dosing

- Chemical metering

- High-viscosity fluid handling

Key Differences Between Centrifugal and PD Pumps

- Flow Control

Centrifugal: Flow changes with system pressure

Positive Displacement: Constant flow regardless of pressure - Viscosity Handling

Centrifugal: Best for thin fluids

PD: Ideal for thick, viscous fluids - Priming Needs

Centrifugal: May require priming

PD: Often self-priming - Efficiency

Centrifugal: Efficiency drops with viscosity

PD: Maintains efficiency across fluid types - Fluid Sensitivity

Centrifugal: Not ideal for shear-sensitive materials

PD: Gentle, consistent handling of sensitive fluids

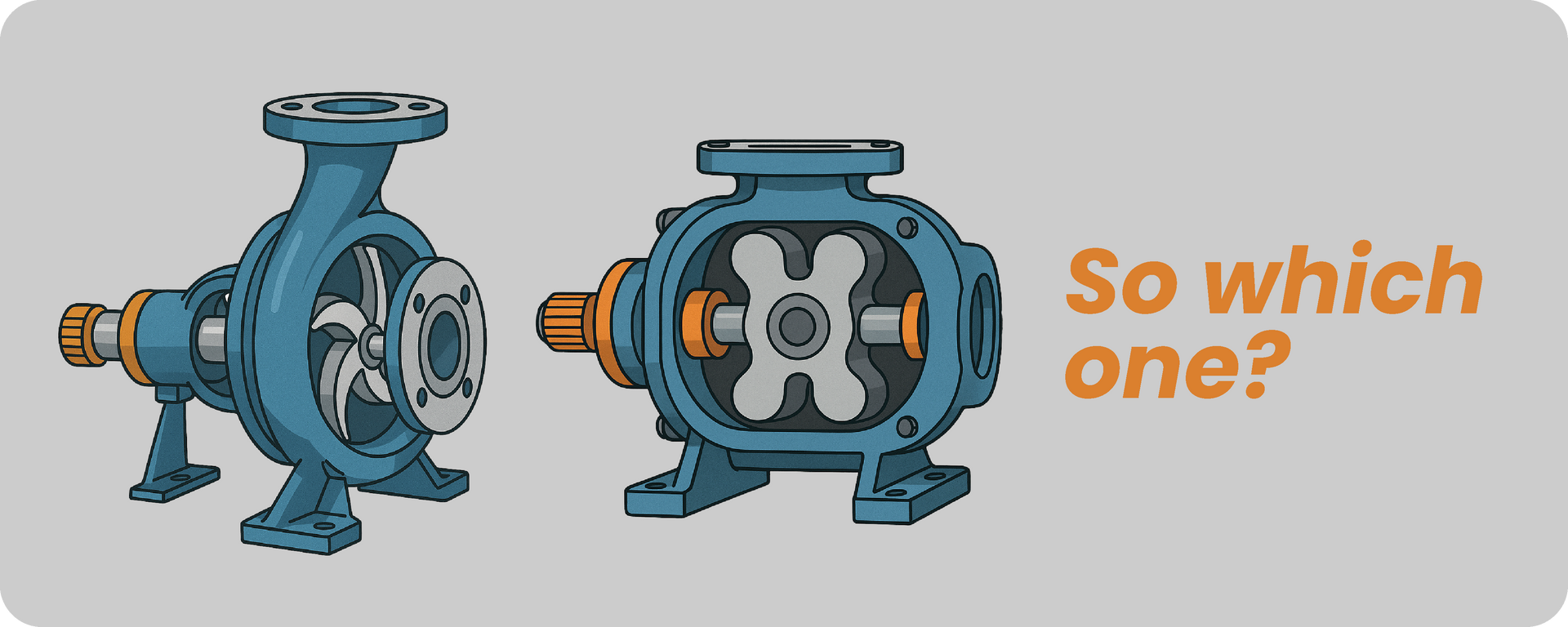

How to Choose the Right Pump

Choosing the right type depends on several factors:

- What is the fluid viscosity?

- Is the flow rate expected to remain constant or vary?

- Are you pumping clean liquids or those with solids?

- How important is dosing accuracy or pressure stability?

If your application involves abrasive solids or high wear conditions, consider reading

Slurry Pumps 101: Selection, Maintenance, and Wear Materials for guidance on selecting materials and configurations that can handle harsh environments.

Common Misapplications to Avoid

- Using a centrifugal pump in high-viscosity applications (will lose efficiency and stall)

- Running a PD pump with the discharge blocked (can damage components if pressure relief isn’t installed)

- Undersizing the motor or misapplying NPSH calculations (can lead to cavitation and premature wear)

Summary Checklist

- Centrifugal pumps are best for low-viscosity, high-flow applications

- Positive displacement pumps excel with thick, pressurized, or metered flow

- Always match the pump to the fluid, flow, and pressure requirements

- Consult performance curves and NPSH data before selection

- Review system friction loss and viscosity impacts before sizing

How Rhino Pumps Can Help

Not sure which pump is right for your system? At Rhino Pumps, we specialize in helping engineers and operators select, specify, and support both centrifugal and positive displacement pumps. Whether you're designing a variable flow process or handling high-viscosity materials, our team provides application-specific guidance, site evaluation, and pump optimization services.

Contact us today to speak with a technical expert or request a quote for your next project.

And if you're troubleshooting pump performance, don't miss our

Top 10 Industrial Pump Problems and How to Fix Them — a practical guide to diagnosing and solving real-world pumping issues.